Future-Ready Separation: XPS Tech PVC Curtains by SPLYPRO

Energy-smart, hygienic barriers that protect product quality, reduce operating costs, and keep operations moving — engineered for modern cold chains and evolving facilities. Based on industry sources and manufacturer data.

Cuts HVAC energy loss — real, measurable savings.

PVC strip curtains reduce air exchange at open doorways, lowering heating/cooling loss and shaving operating costs.

Stabilizes temperatures for process reliability and spoilage prevention.

By creating a flexible barrier, strips keep different zones thermally separate reducing temperature cycling that harms perishable stock and sensitive processes.

Improves sanitation & keeps out pests/debris — important for food and pharma.

Transparent PVC strips block insects, dust, and airborne debris while allowing traffic — a simple engineering control that supports food-safety programs and health-department requirements.

Reduces noise and improves worker comfort

Thicker vinyl strips act as a sound barrier between noisy zones (loading docks, welding areas) and quieter office or packing spaces, helping staff concentration and hearing-safety efforts.

Adds safety, visibility, and specialized protections

Clear PVC maintains sight lines (forklift/pedestrian safety) while optional formulations offer flame retardancy, mildew resistance, or permanent antistatic properties for ESD-sensitive or fire-rated applications.

Low cost, low maintenance, and future-proofing for flexible facilities

PVC strips are relatively inexpensive to buy/replace, easy to repair (swap a strip, not a door), and adaptable to automation or cold-chain upgrades

XPS Tech PVC Curtains Offers

Flexible Barriers, Maximum Efficiency

Frequently asked questions

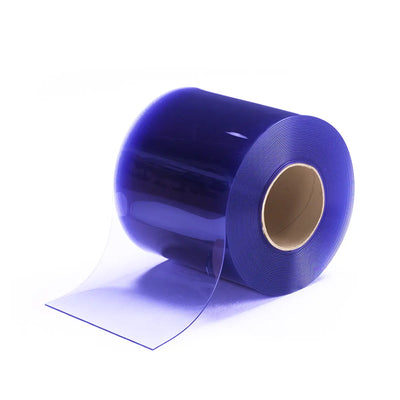

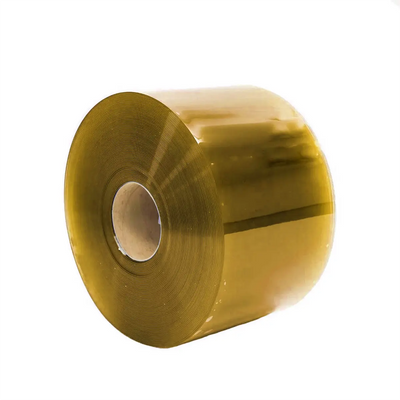

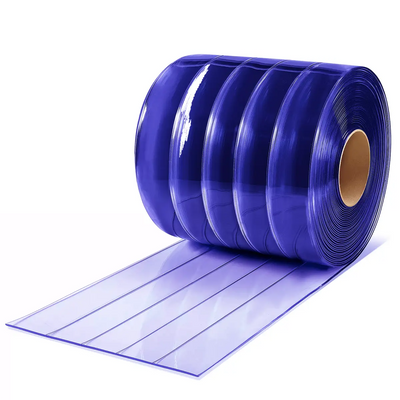

XPS Tech PVC rolls are designed to create flexible strip curtains that reduce energy loss, separate temperature zones, and block dust, pests, and noise — while maintaining visibility and safe traffic flow.

Yes. Each roll (available in smooth or reinforced formats) can be cut to fit doorways, partitions, or industrial openings of any size.

SPLYPRO offers XPS Tech rolls in multiple widths (8", 12") and thicknesses (0.080", 0.120") with roll lengths up to 300 ft, so you can select the right balance of durability, flexibility, and traffic type.

Absolutely. XPS Tech strips are formulated for clear visibility and temperature resistance, making them ideal for walk-in coolers, freezers, and food-processing facilities.

They minimize air exchange when doors remain open, reducing heating and cooling loss by up to 20% depending on traffic and facility conditions.

Yes. Nylon-reinforced PVC strips offer higher tensile strength and tear resistance, making them better suited for heavy-traffic industrial areas and forklift entryways.

Standard smooth PVC strips remain flexible from −10 °F to +140 °F, while reinforced and low-temperature formulas extend usability for cold storage down to about −20 °F.

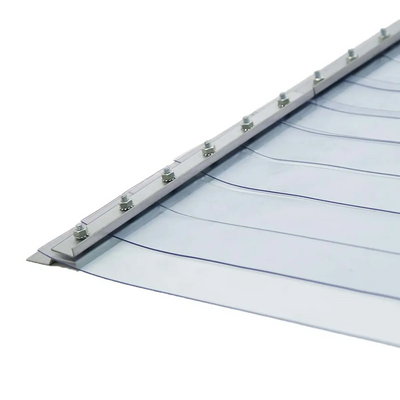

Simply cut strips to your desired length and mount them using a strip curtain hardware kit or hanging system. Strips can overlap for added insulation and can be replaced individually when worn.

Yes. One of the main benefits of PVC strip curtains is easy maintenance — you can replace individual strips without removing the entire curtain system.

XPS Tech rolls are engineered with smooth clarity, reinforced strength options, and long-roll formats that reduce waste and installation time, ensuring professional-grade performance for modern facilities.