- Sku: 17-0013

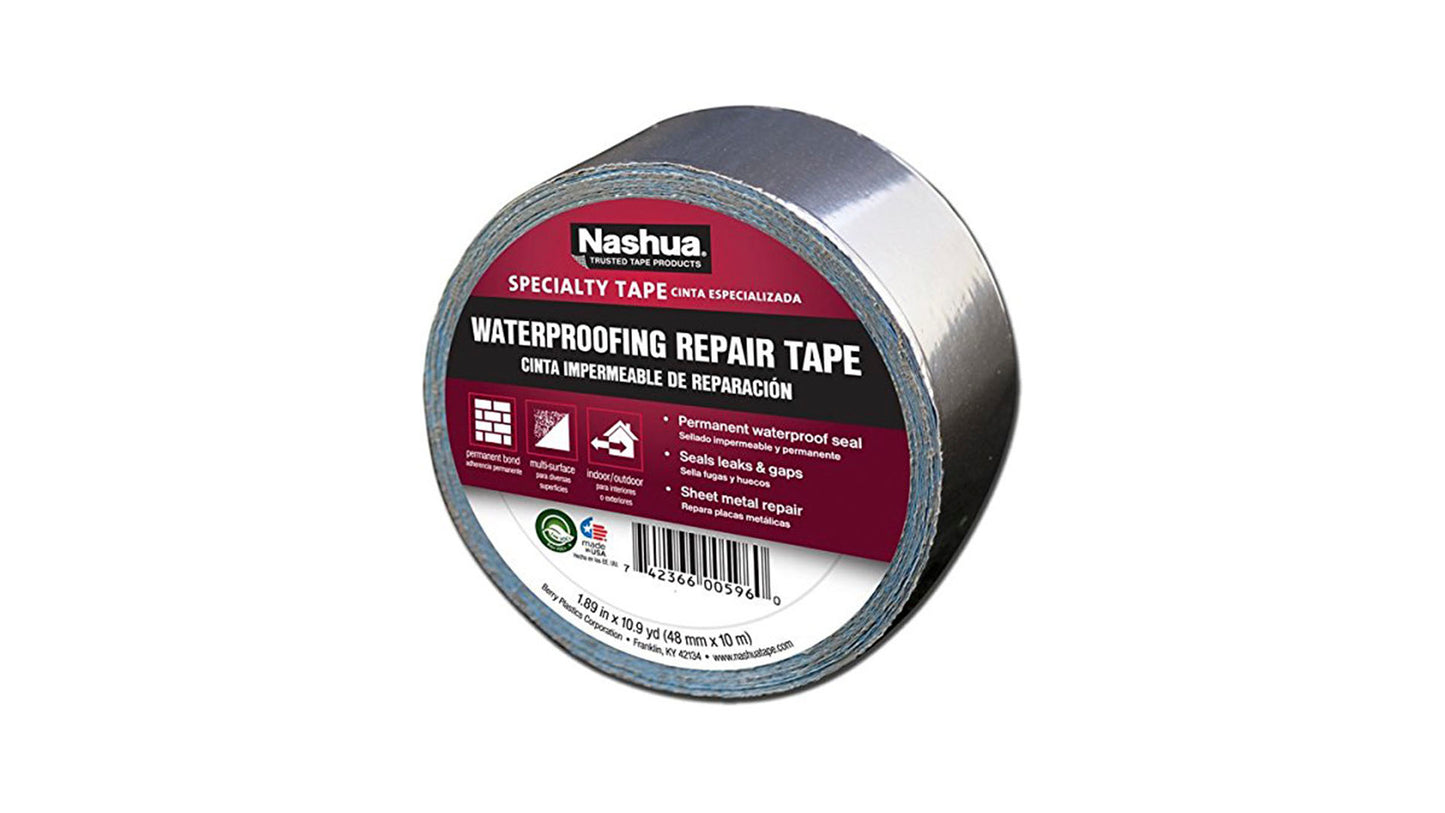

Nashua 361-11 Waterproofing Repair Tape

💸 BEST PRICE

We back all products with a 1-year guarantee.

📦 Free Shipping Policy

We’re proud to offer free shipping on qualifying orders within the continental U.S. on orders of $50 or more:

- Remote Locations: Unfortunately, we do not offer free shipping to remote areas (including Alaska, Hawaii, Puerto Rico, and outlying territories) due to increased carrier costs. Standard shipping rates will apply.

Shipping zones are calculated automatically at checkout based on your delivery address.

Nashua 361-11 Waterproofing Repair Tape

The Nashua 361‑11 Waterproofing Repair Tape features an aluminum foil backing with butyl rubber adhesive for a waterproof, permanent seal. Moreover, it is extremely conformable to fit irregular surfaces and resists cold, heat, water, and sunlight, ensuring dependable performance in all climates.

Certified Performance

Certified to UL723 for fire safety, this tape combines an 11-mil total thickness (9 mil adhesive, 2 mil foil) with 75 oz/in adhesion and 20 lb/in tensile strength, making it ideal for demanding HVAC and roofing repairs. Furthermore, its LDPE release liner peels away cleanly for quick application.

Applications & Benefits

This tape is paintable, allowing seamless color matching on metal panels, gutters, and roofs. It seals leaks, repairs seams, and protects against moisture in both indoor and outdoor settings. As a result, technicians and contractors save time and materials by using one versatile solution.

What is a Mil Thickness?

- Thickness, AKA caliper or gauge, refers to the distance from one surface of a tape backing, or adhesive, to the other.

- 1 MIL = 1/1000 OF AN INCH

- Examples: 1/16 inch = 62.5 mils; 1/32 inch = 31.25 mils

Have a question?

Nashua 361-11 Waterproofing Repair Tape

FREE SHIPPING — Orders $50🔥 when you sign in or sign up for an account.